The Challenge

An aerospace component manufacturer needed a better way to manage material replenishment across their production floor. Like many manufacturers, they faced common challenges with their existing process:

The manual coordination required for reordering parts created bottlenecks:

- Multiple handoffs between operators, supervisors, and purchasing

- Time-consuming communication to trigger replenishment

- Limited real-time visibility into what had been reordered

- Risk of production delays when parts ran low

- Manual data entry creating potential for errors and delays

The company wanted to implement lean manufacturing principles - specifically the Kanban methodology - but needed a digital solution that would integrate seamlessly with their existing Odoo ERP system.

The Solution: Digital Kanban for Odoo

The aerospace manufacturer selected S4 Solutions' Kanban for Manufacturing app because it offered:

Native Odoo Integration Built specifically for Odoo with no complex middleware or custom integration required

Simple Interface Intuitive enough for operators to use directly on the factory floor

Flexible Order Types Supports purchase orders, manufacturing orders, and warehouse transfers - all from the same system

Barcode Scanning Works with tablets, smartphones, or dedicated barcode scanners

Lean Methodology Based on proven Kanban principles used successfully in manufacturing for decades

Implementation

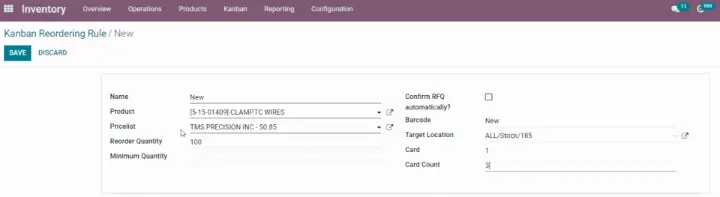

The implementation process was straightforward. The team configured Kanban parameters for their parts, including reorder quantities, delivery locations, and the number of cards to use in each loop.

The configuration screen makes setup simple - enter parameters and you're ready to generate cards

How It Works in Practice

The system generates professional Kanban cards with all relevant information and a scannable barcode. These cards are attached to parts bins.

Each Kanban card includes part details and a scannable barcode

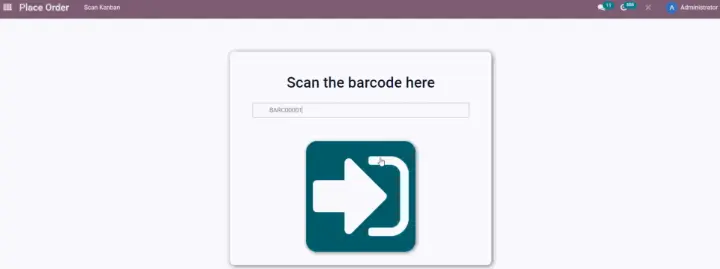

When parts reach their reorder point, operators scan the Kanban card using a barcode scanner. The aerospace manufacturer uses iPads with scanning capability.

The scanning interface works with any mobile device - tablets, smartphones, or barcode scanners

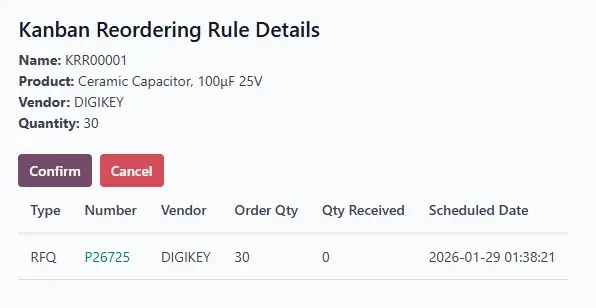

After scanning, the system displays order details for review. The operator confirms with a single tap.

Operators review and confirm orders in seconds

The system automatically creates the appropriate order in Odoo:

- Purchase orders to suppliers (using Odoo Vendor Pricelists)

- Manufacturing orders for internally produced components

- Warehouse transfers for moving inventory between locations

Everything integrates with the company's existing Odoo workflows, providing purchasing, manufacturing, and warehouse teams with real-time visibility.

The Impact

The Kanban for Manufacturing implementation has transformed the aerospace manufacturer's replenishment process:

Streamlined Communication

The multiple handoffs previously required between operators and purchasing have been eliminated. A single scan triggers the entire replenishment process automatically.

Faster Response Time

Replenishment orders are created immediately when parts reach reorder points, eliminating delays from manual communication and data entry.

Improved Visibility

Management now has real-time access to replenishment activity through Odoo's dashboards and reports, replacing manual tracking methods.

Operator Efficiency

Operators can trigger replenishment in seconds with a simple scan and confirmation, allowing them to focus on their primary work.

Easy to Learn

The intuitive interface requires minimal training. Operators can learn the complete process quickly.

Seamless Integration

Because Kanban for Manufacturing is built natively for Odoo, it works perfectly with the company's existing purchasing, manufacturing, and inventory modules. No custom integration was required.

Scalable System

The company continues to expand their Kanban implementation to additional parts and work areas as they see the benefits in action.

The Technology

The Kanban system integrates directly with Odoo's core modules:

Purchasing Integration

- Automatic purchase order creation using configured vendor pricelists

- Seamless workflow for purchasing team review and approval

- Supplier communication through standard Odoo processes

Manufacturing Integration

- Manufacturing orders created automatically for internal production

- Integration with bills of materials and routing

- Standard MRP workflow

Inventory Integration

- Warehouse transfers between locations

- Real-time inventory tracking

- Standard Odoo inventory management

Multi-Device Support

- Works with iPads, tablets, smartphones

- Compatible with dedicated barcode scanners

- No special hardware requirements

Looking Forward

The aerospace manufacturer continues to expand their use of Kanban for Manufacturing, implementing it for additional parts and production areas. The system has proven to be an effective way to bring lean manufacturing principles into their Odoo environment.

Is Digital Kanban Right for Your Operation?

Kanban for Manufacturing may be a good fit if your operation experiences:

- Manual coordination required for replenishment

- Time spent on communication between floor and purchasing

- Limited visibility into replenishment status

- Desire to implement lean manufacturing principles

- Need for integration with Odoo ERP

Learn More About Kanban for Manufacturing

Contact us at info@sfour.io to discuss how digital Kanban could work in your operation.